Kostenreduzierung

und geringeres Risiko.

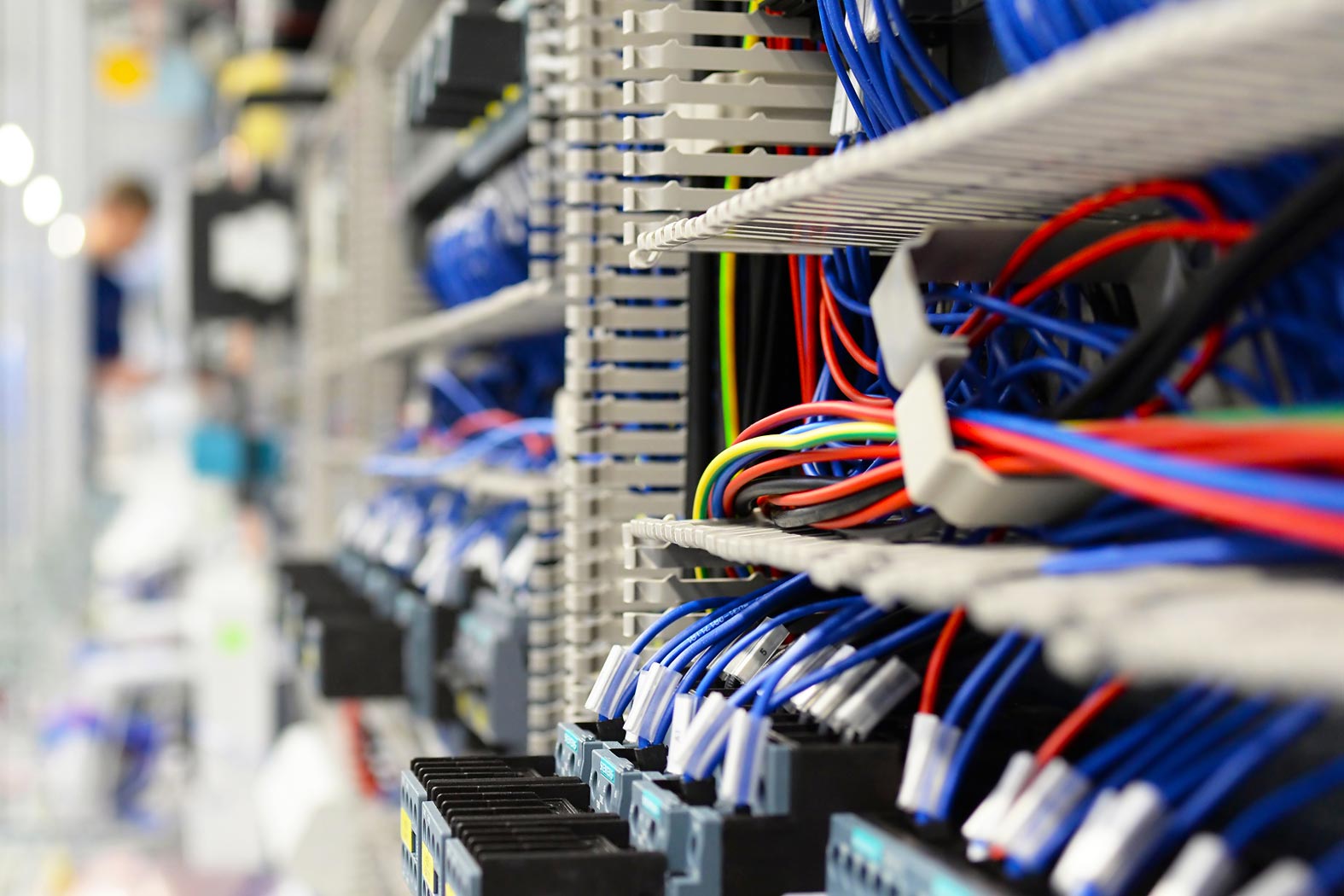

Mit WSA rechnet sich das Ausgliedern Ihrer Abfallentsorgung an einen Spezialisten. Wir erstellen Ihnen gerne ein unverbindliches Angebot.

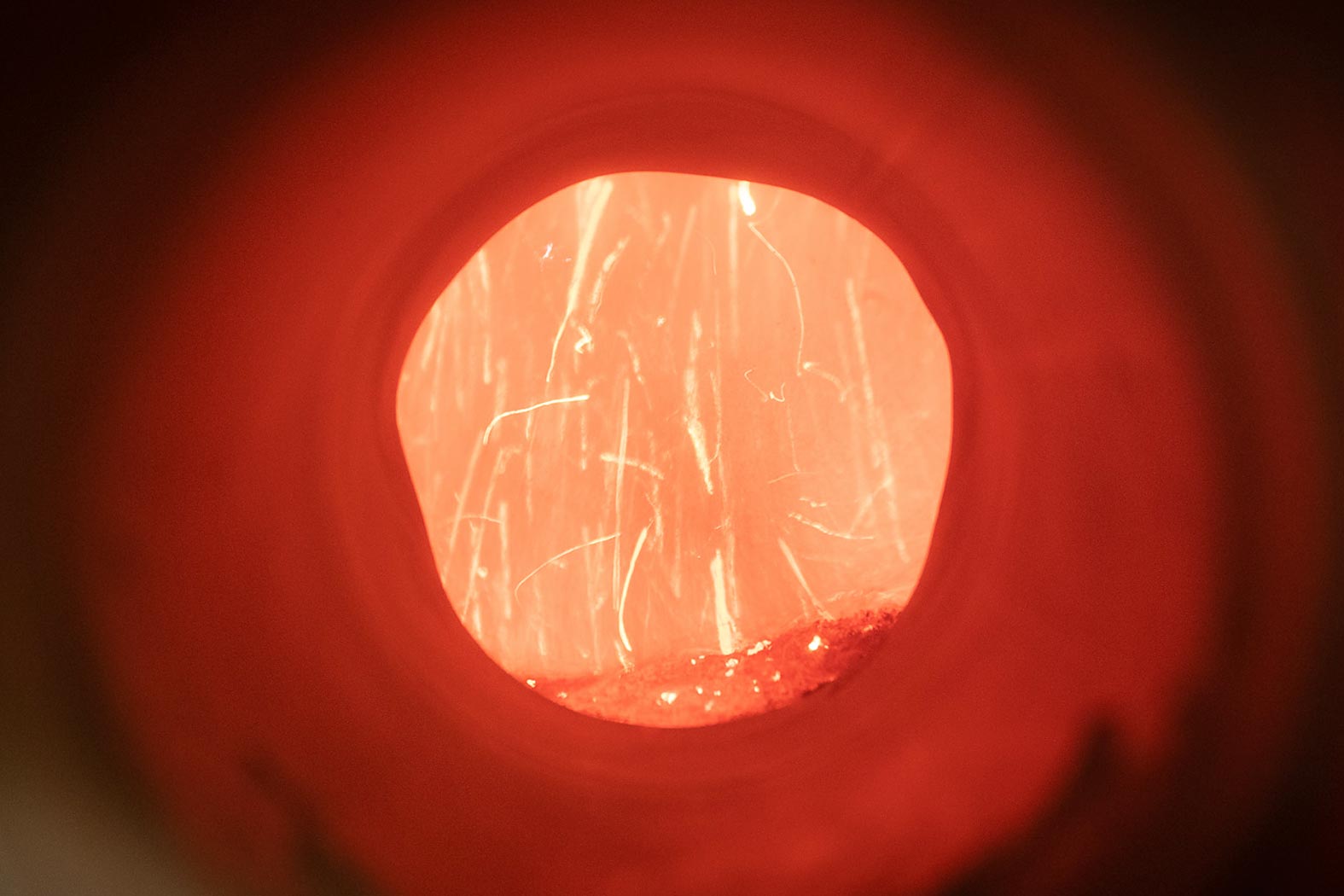

- Zertifizierter Entsorgungs-Fachbetrieb

- Umweltschutz & Rechtsicherheit